Siemens PLC cables

- Omron PLC cables

- Mitsubishi PLC cables

- Idec / Izumi PLC cables

- Unitronics PLC cables

- Z-World micro-controller cables

Programming cables for Siemens PLCs

Most PLCs manufactured by Siemens are not equipped with a normal RS232 port. On the S5 PLC series, a TTY 20 mA current loop interface is used. The S7 series on the other hand use a PPI or MPI interface. A simple programming cable between a PC and a Siemens PLC is therefore not possible. Some electronics is necessary to perform the necessary signal conversion. Some peripherals like the OP display can however be connected directly with a serial port.

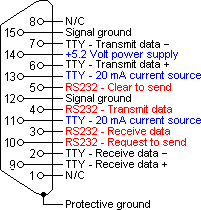

Pin assignment for the Siemens S5 DB15 connector

On Siemens S5 PLC systems and peripherals, a DB15 connector is used for serial communications. This connector is present on CPUs, communication processors and operator panels, and in all cases the used pins and functionality slightly differ. The picture and table below show the general pin assignment of the Siemens S5 DB15 connector.

| Pin | Name | CPUs | Comm. Processors | HMI Panels |

|---|---|---|---|---|

| 1 | n/c | – | – | – |

| 2 | TTY – Receive data – | Yes | Yes | Yes |

| 3 | RS232 – Receive data | No | Yes | Yes |

| 4 | RS232 – Transmit data | No | Yes | Yes |

| 5 | RS232 – Clear to send | No | Yes | Yes |

| 6 | TTY – Transmit data + | Yes | Yes | Yes |

| 7 | TTY – Transmit data – | Yes | Yes | Yes |

| 8 | n/c | – | – | – |

| 9 | TTY – Receive data + | Yes | Yes | Yes |

| 10 | RS232 – Request to send | No | Yes | Yes |

| 11 | 20 mA current source | Yes | some models | some models |

| 12 | Signal ground | Yes | Yes | Yes |

| 13 | 20 mA current source | Yes | some models | some models |

| 14 | +5.2 Volt power suplply | Yes | some models | some models |

| 15 | Signal ground | Yes | Yes | Yes |

Based on limited available data, errors may be present

Although the pin assignment on the various DB15 connectors on Siemens S5 devices is consistent, the availability of specific signals varies a lot. The TTY 20 mA current loop input and output are available on all devices, but the current source to power this communication is only found on the CPUs and a few of the other devices. RS232 signals on the other hand are not available directly on the CPU programming port, but most communication processors and operator panels provide them.

Siemens has solved the problem of different capabilities of the DB15 connectors on various equipment at the programmer side, by adding an active (powered) TTY 20 mA current loop interface in their programming devices. For PLC programming with a normal PC, the passive (unpowered) 6ES5-734-1BD20 RS232 to TTY adapter cable is used. Because this is a passive cable, it must be powered by the +5 Volt power source on pin 14 on the DB15 connector. As this power source is not available on all devices with a DB15 connector, success rate with the 6ES5-734-1BD20 cable may vary.

Electronics layout for a Siemens S5 RS232 to TTY converter

If you need high quality communications between the RS232 port on a PC and a Siemens S5 PLC or another device from the S5 series, I advice you to buy the original 6ES5-734-1BD20 converter cable. It is solid, and guaranteed to work. The price of this cable is however high, and availability is getting worse because the S5 PLC series is no longer manufactured by Siemens. Therefore I offer on this site an electronics layout you can use to create your own RS232 to TTY converter. This information is provided for educational purposes only. No guarantee is given that the solution will work in your specific situation, and no responsibility is taken for any loss or damage resulting from the creation of a converter based on this information.

On the S5 series CPUs from Siemens, a DB15 connector is present to connect a programming cable to. This connector does not provide normal RS232 pins. Instead, isolated 20 mA current loop TTY inputs and outputs are used for the communication. This gives a galvanic isolation between the PLC and the connected computer. Although the signal levels on this TTY interface are different from the RS232 standard, the bit sequences are the same. The electronics between the TTY port on the PLC and the RS232 port on the computer does therefore only have to convert the signal levels. There is no protocol conversion taking place.

The easiest way to convert RS232 signal levels to 20 mA current loop levels is by first converting the RS232 level to TTL, then use an opto-coupler for the current transformation. Many opto couplers work in the 20 mA range which make this solution feasible without much extra electronics. The conversion from RS232 to TTL levels can be done with a converter from the Maxim MAX232 chip family.

Although the MAX232 converter chip is the cheapest and most used in the Maxim family, I prefer to use the MAX233. This chip has the advantage that the internal DC/DC converters don’t need external capacitors, further simplifying the design.

The electronics need power to operate. Three different solutions come to mind. In the first approach, the power from the RS232 handshaking lines is used and converted to the appropriate levels. In the second approach, the 5 Volt power on the DB15 connector on the PLC is used. The third possibility is to use an external power supply.

All power supply sources have their pro’s and con’s. Many modern RS232 ports are not capable to generate enough power for external electronics. The 5 Volt power source on the DB15 is only available on the S5 CPUs, but not on peripherals like for example the communication processors CP526 and CP527, or some OP display series equipped with a TTY port. Furthermore, by using this +5 power supply, there is no galvanic isolation anymore between the PLC and PC. To keep the connection isolated, an DC/DC converter must be used, making the design more difficult.

The most versatile solution would be to use an external power source. For this design, I will use a layout where the RS232 port and an external power source can both be used. If you want to, you can replace the external power source by a DC/DC converter, powered by pin 14 on the DB15 connector.

Even more cables…

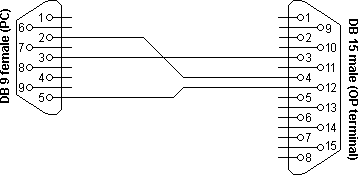

The Siemens operator terminals can be programmed using a normal serial cable. The following cable can be used to program the OP series of operator displays.

|

If an item is advertised as "under $50.00",

you can bet it's not $19.95.

Mc GOWAN'S CHRISTMAS SHOPPING AXIOM

|